The Wedged Wire Screen Welding Machine/Water well screen welding machine/wedged screen welding machine/johnson pipe welding machine is a specialized piece of equipment designed for the production of wedge wire screens. Wedge wire screens, with their unique structure and excellent filtration performance, are widely used in industries such as oil, chemicals, water treatment, mining, and food processing.

The specifications of the Wedge Wire Screen Making Machine :

|

Wedge wire

|

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70

Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

Diameter

|

from 25mm to 1200mm.

|

|

Support rod

|

Width(mm): 2.30 3.00 3.30 3.70

Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

End connection

|

Plain beveled ends, flanged or threaded couplings

|

|

Slot size

|

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request.

|

Certification

|

ISO9001

|

|

Material

|

Galvanized low carton (LCG), stainless steel (304,316 etc.)

|

Length

|

up to 6m

|

Features of the Machine

Precise Welding Technology

The machine adopts advanced automatic welding technology to ensure a strong, precise bond between the wedge wire and the support rods. This results in high welding strength and product consistency.

High Production Efficiency

With high automation, the machine can perform continuous welding, significantly increasing production efficiency, making it ideal for large-scale production needs.

Versatile Specifications

The machine can produce wedge wire screens in a variety of shapes and sizes, including round, oval, and curved, making it adaptable to different application scenarios.

Easy Operation

The machine is equipped with a user-friendly control panel and intuitive operating system, allowing users to quickly operate the machine with minimal training.

Durability and Longevity

The machine is designed with a robust structure and made of high-quality materials, ensuring long service life and low maintenance costs.

The Wedged Wire Screen Welding Machine works by wrapping the wedge wire around a rotating mold while using resistance welding technology to fuse it with the support rods. The gap between the wires can be adjusted to meet specific needs, ensuring optimal filtration and permeability performance.

· Water Treatment: Used for filtering wastewater or separating solid particles.

· Oil and Gas: Applied in drilling fluid filtration and sand control in wells.

· Food and Beverage: Utilized for separating impurities and filtering liquids.

· Mining: Used for ore screening and tailings filtration.

· High Filtration Precision: The wedge wire structure prevents clogging and enhances filtration efficiency.

· Strong Corrosion Resistance: Suitable for harsh and corrosive environments.

· Flexible Production: Customizable screen specifications and shapes according to customer requirements.

The Wedged Wire Screen Welding Machine, with its reliable performance and excellent craftsmanship, is an indispensable piece of equipment in the screen manufacturing industry. It is the ideal choice for improving production efficiency and product quality.

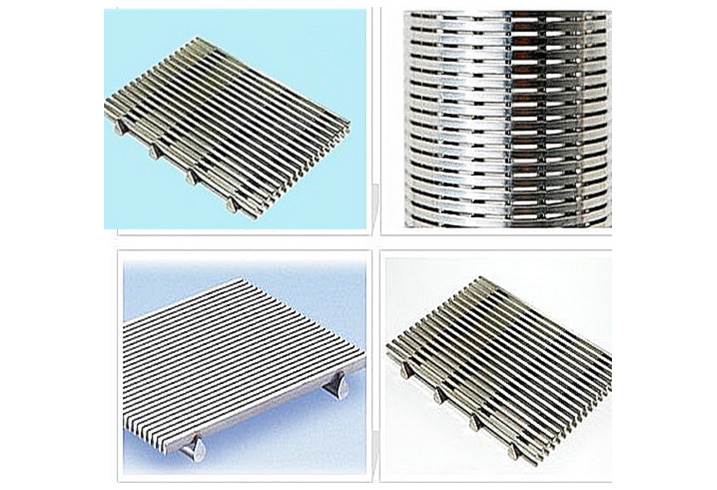

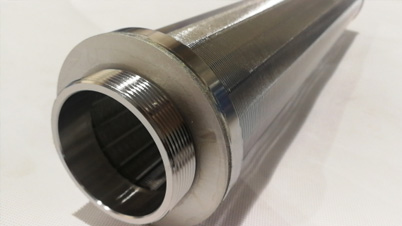

Finished Product Picture

[video width="272" height="480" mp4="/wp-content/uploads/2025/06/WeChat_20250621095857.mp4"][/video]