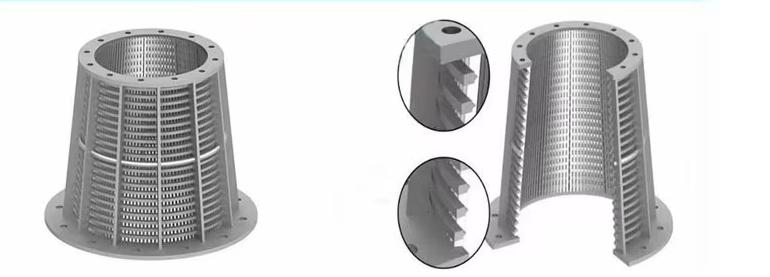

Stainless Steel Filter Basket application of Centrifuge in Sulfonate Recovery Plant with C9 Arene

Materials: Generally, stainless steel grades such as 304, 304L, 304HC, 316, 316L, 321, and 430 are used. Titanium alloy, carbon steel, or painted steel plates can also be employed. Additionally, high molecular materials can be selected based on specific requirements.

Working Principle

By taking advantage of the effect of centrifugal force, substances of different densities generate different centrifugal forces under high-speed rotation, thus achieving separation. Once the centrifuge starts, the solid-liquid mixture rotates along with it. Large particles are flung to the edge of the centrifuge basket, while small particles pass through the screen of the basket and flow towards the discharge outlet.

Type